Replacing an Oil Pan Gasket Without Disconnecting the Transmission!

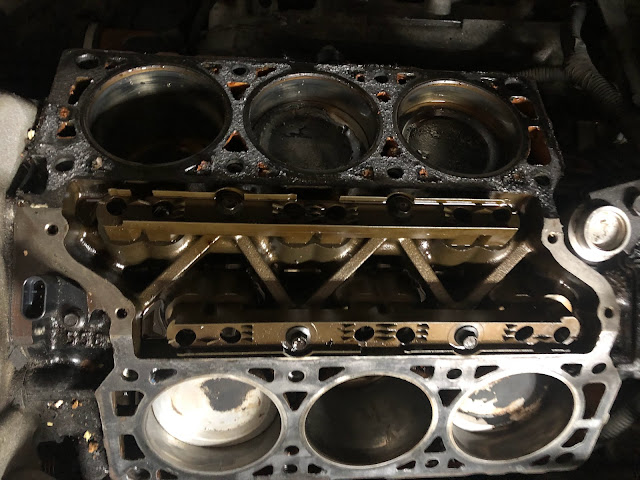

Our 2004 Malibu LT had a slow oil leak. Over the Fourth of July, it progressed to a small puddle of oil in the driveway. It took some time to investigate the cause and a little courage to turn some bolts, but now the car is leak-free. Here’s a recap of what I did. The car was leaking on the front of the engine, which in this car means the passenger side. Observing the area by the crankshaft was difficult because the splash shield is a two-part component. Upon inspection, the front seal looked like it was leaking. I cleaned it up and the boss around the seal, and put the liner back in place. Cleaned front seal and boss. Almost immediately, the car started leaking again. A week later, when I re-inspected the front seal, it was clean, as was the boss. I thought it could be the oil pan gasket, the timing cover gasket, or the oil filter adapter gasket. I cleaned the area around the oil p...